|

|

"If you have a bore that you

haven't been able to drill, chances are the INCREDIBIT® will drill it."

|

|

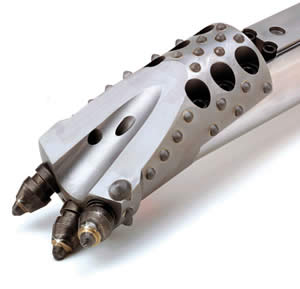

Railhead's INCREDIBIT® drill head is named for

its ability to bore and steer through tough, rocky conditions.

Its patented technology allows contractors to accomplish

bores in ground that can not be drilled with conventional

bits.

And, it allows smaller machines to drill through some

conditions that would otherwise require a mud motor. It

is truly a multipurpose bit that steers through soft conditions

as well as rock and cobble.

|

|

How the Incredibit® works

|

The INCREDIBIT® bores in an entirely different

manner than any other bit. Rather than using simple abrasion,

the INCREDIBIT® fractures rock in a random elliptical

pattern. It "dances" in the hole, allowing the

INCREDIBIT® to be productive in all kinds of soils

and formations.

|

Because of the "dancing"

effect, the INCREDIBIT® bores a larger hole than conventional

bits. In most conditions, a 2 ¾" bit will

cut approximately a 4" hole, a 3" bit will cut

approximately a 5" hole, a 3 ½" bit will

cut approximately a 6" hole, and a 4 1/8" bit

will cut approximately an 8" hole.

|

|

|

DRILLING

|

The

drilling technique used with the INCREDIBIT¨ is similar

to a flat bill bit in softer formations, however, when drilling

in harder formations it is important to not force the bit, but

let it drill at it's own pace.

Apply steady pressure. We recommend starting with 500 pounds

of forward thrust and increase pressure as needed based on the

conditions of the bore site. Rotational torque may also start

at 500 pounds. Simply allow the bit to work while maintaining

enough pressure to accomplish the job.

|

STEERING

|

Steering in soft

formations is similar to steering with a flat bill - turn and

push. Steering in harder formations requires more technique.

The best method to use is to push into the rock and cut over

to create a relief, pull back, rotate, and do it again.

If you wanted to go to 12 o'clock - you would push in at 10

and rotate over to 2 while applying heavy force. Repeat this

action as many times as necessary to carve in about one foot,

then check your pitch. Continue until the desired pitch has

been reached. This is the only time we recommend increased pressure.

Use only enough force to score the rock and create a relief.

Drilling in different formations requires varying your drilling

techniques. The most common problem you will encounter is layered

formations.

It is difficult to steer when the layers are running at the

same or at a close angle to the pitch you are trying to achieve.

Generally there is a spot somewhere in the layer that you can

catch and turn. Where that is - is anybody's guess.

The key is to be patient and continue to cut and rake until

you find it. Sometimes you can pull back, find another angle

of attack, then come back up with more pitch to get enough angle.

Most holes are saved because of the operator and his familiarity

with the machine and the bit.

|

|

DESIGN

FEATURES

|

US patents 5,931,240 5,934,391 6,209,660. Canadian patent

2,221,068 |

| |

| |

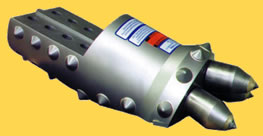

The INCREDIBIT®

comes in two configurations for different rock hardness formations: |

Standard |

1. The Standard INCREDIBIT®

for boring soft to medium hardness rock formations. |

|

Agressive |

2. The Aggressive INCREDIBIT®

for easier boring in harder rock. |

|

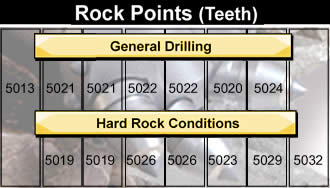

Replacable

Teeth |

Rock teeth play

an important role in getting the most productivity out of your

INCREDIBIT®.

As the teeth come in contact with rock, the combination of torque

and pressure create cracks in the rock and force small pieces

of rock to break away. Generally speaking, sharp pointed teeth

are more effective in softer conditions and rounded teeth are

more effective in harder conditions.

The chart shows which teeth are the most effective for general

drilling and hard drilling conditions. However, these recommendations

may not work in all situations. |

|

|

|

Interference

Keyway

The INCREDIBIT® is fitted with an "interference keyway"

that relieves the side stress on the bolts that secure the bit

to the sonde housing.

|

|

Repairable

Any tool used to bore in adverse ground conditions will sustain

wear. The good news is, within reason, the INCREDIBIT® can

be rebuilt. |

|

|

Got a BIG rig?

Now you can get an Incredibit® made especially for

the BIG machines.

|

Big rigs 50,000 lbs.+ can have

the amazing Incredibit® too!

It can cut a 10" to 12" hole and is available

with a 5" sonde housing.

The incredibit drill head is named for it's incredible ability

to bore and steer through almost anything: hard blue shale,

sandstone, limestone, concrete, anything in it's path.

|

|

|

|

|

|

|

|